Would you like to reduce your spend on additives? Do you have the secret of achieving high quality casting surface finish? Are you concerned about optimising your green sand process, or reducing casting defects, or making the foundry more profitable?

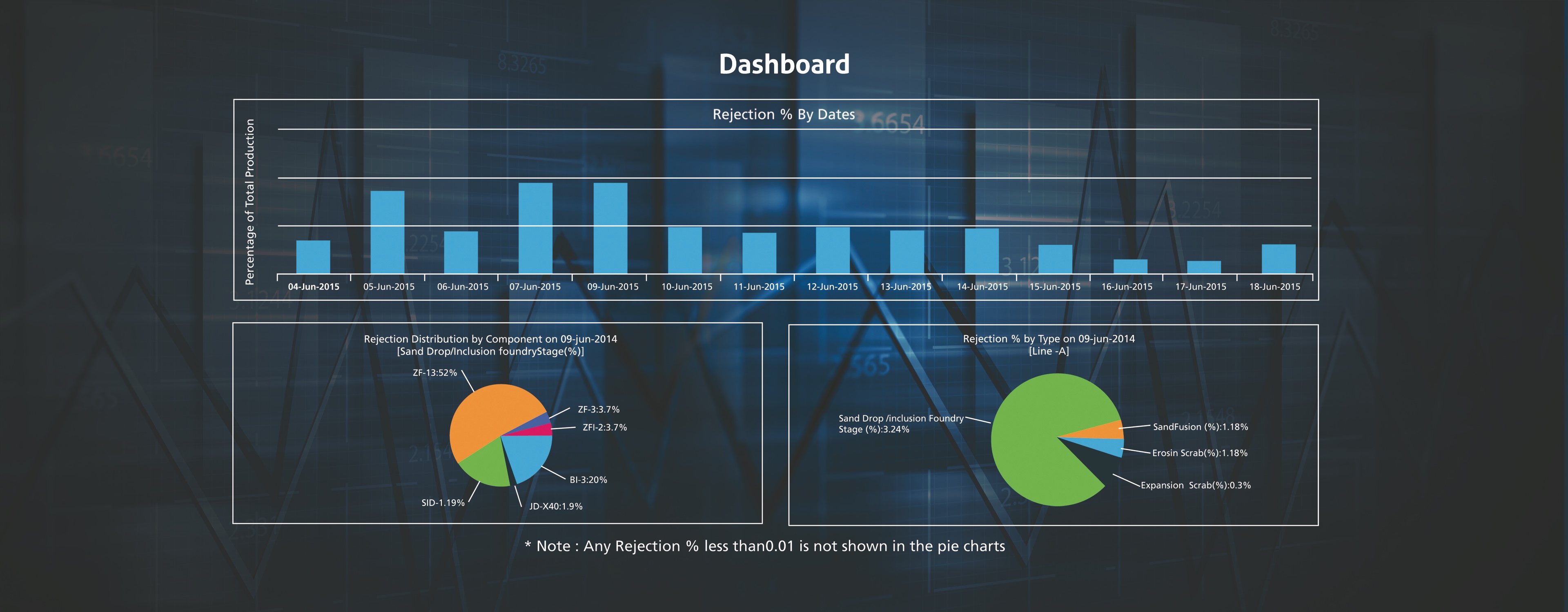

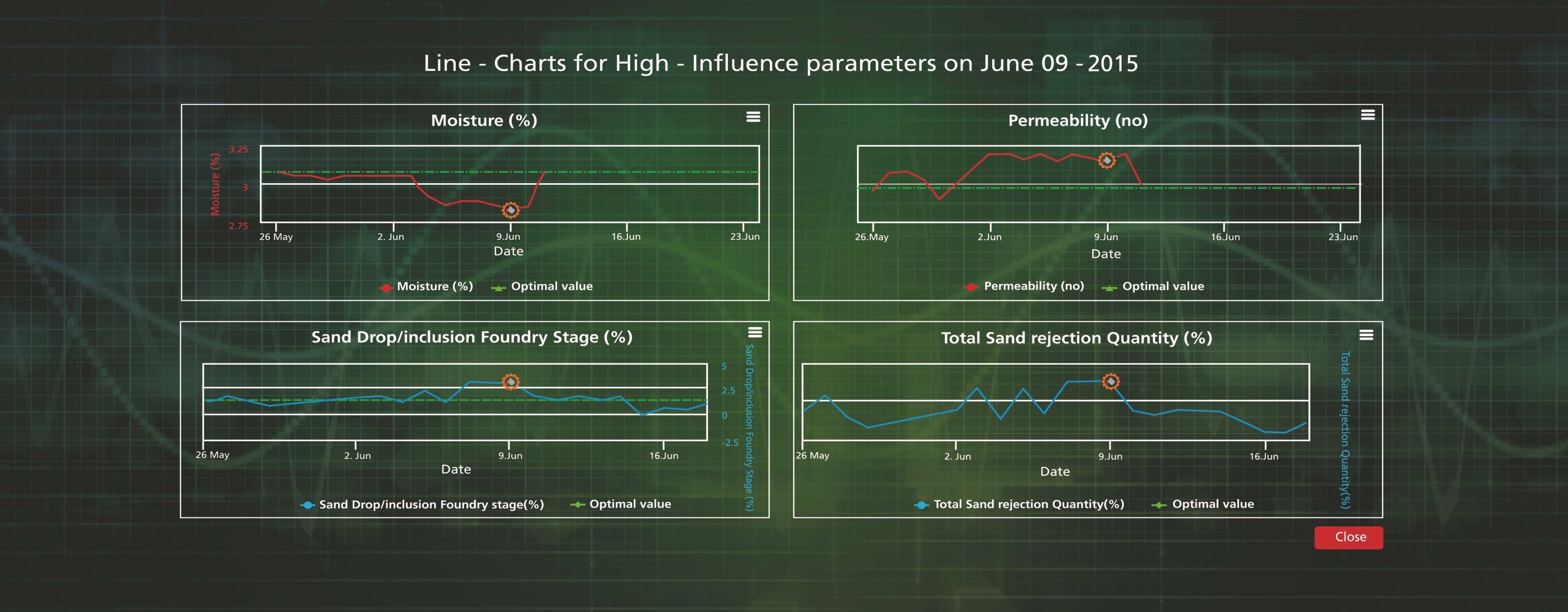

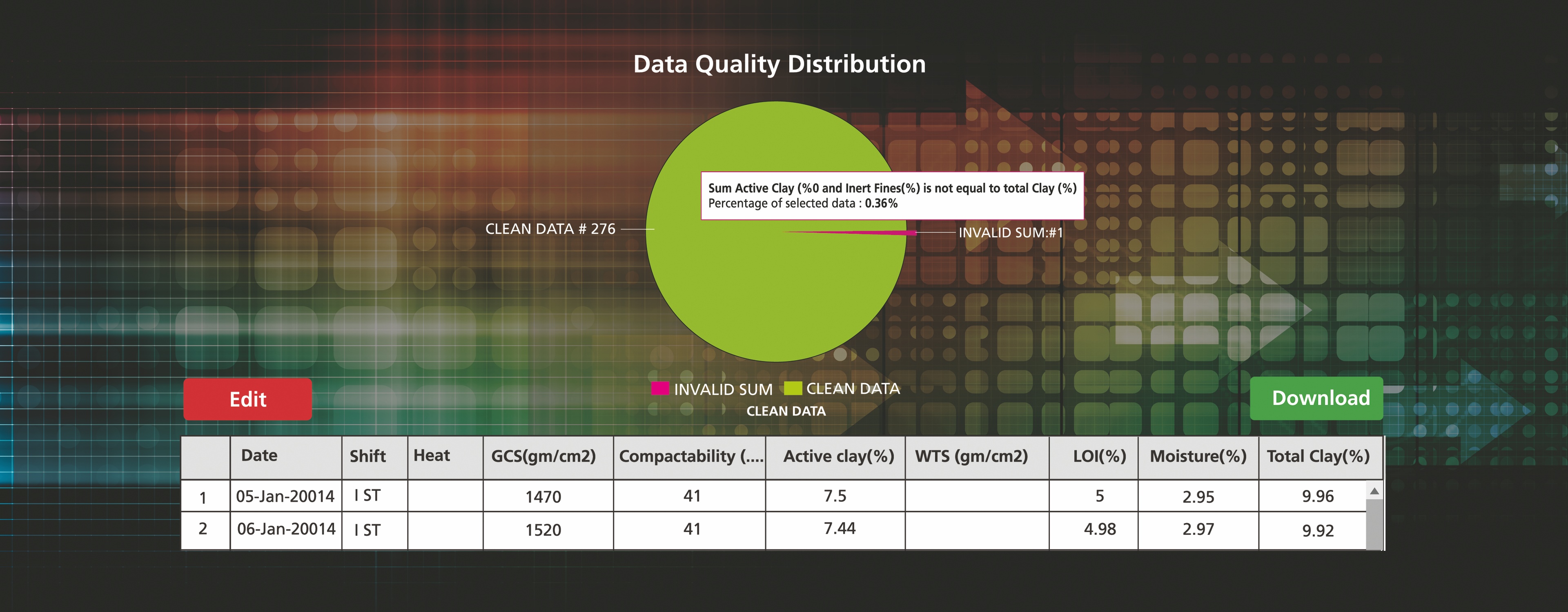

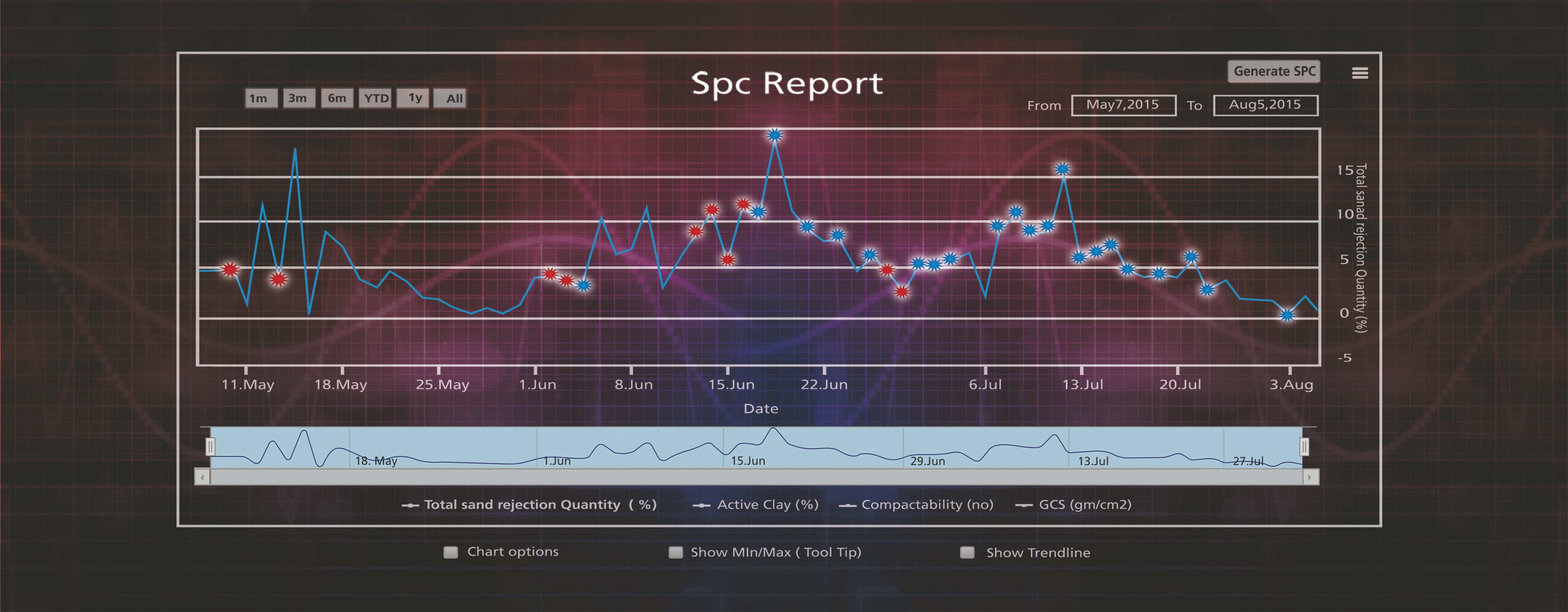

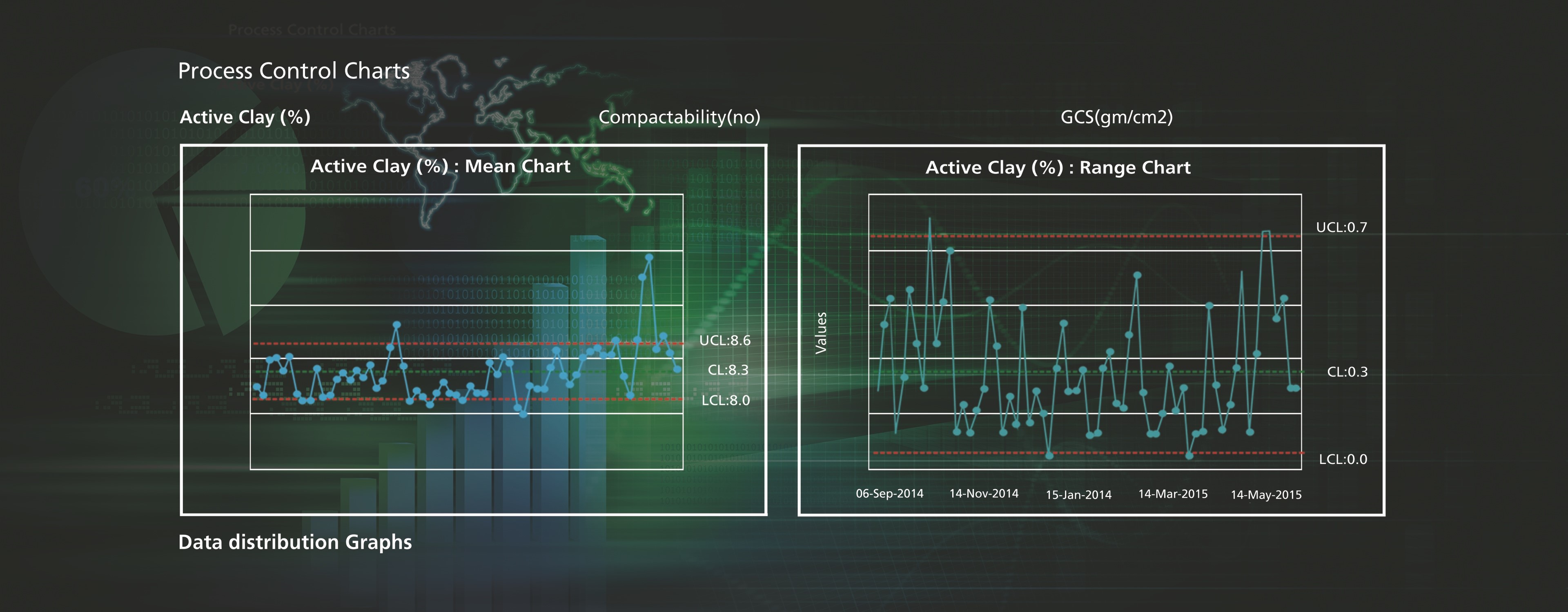

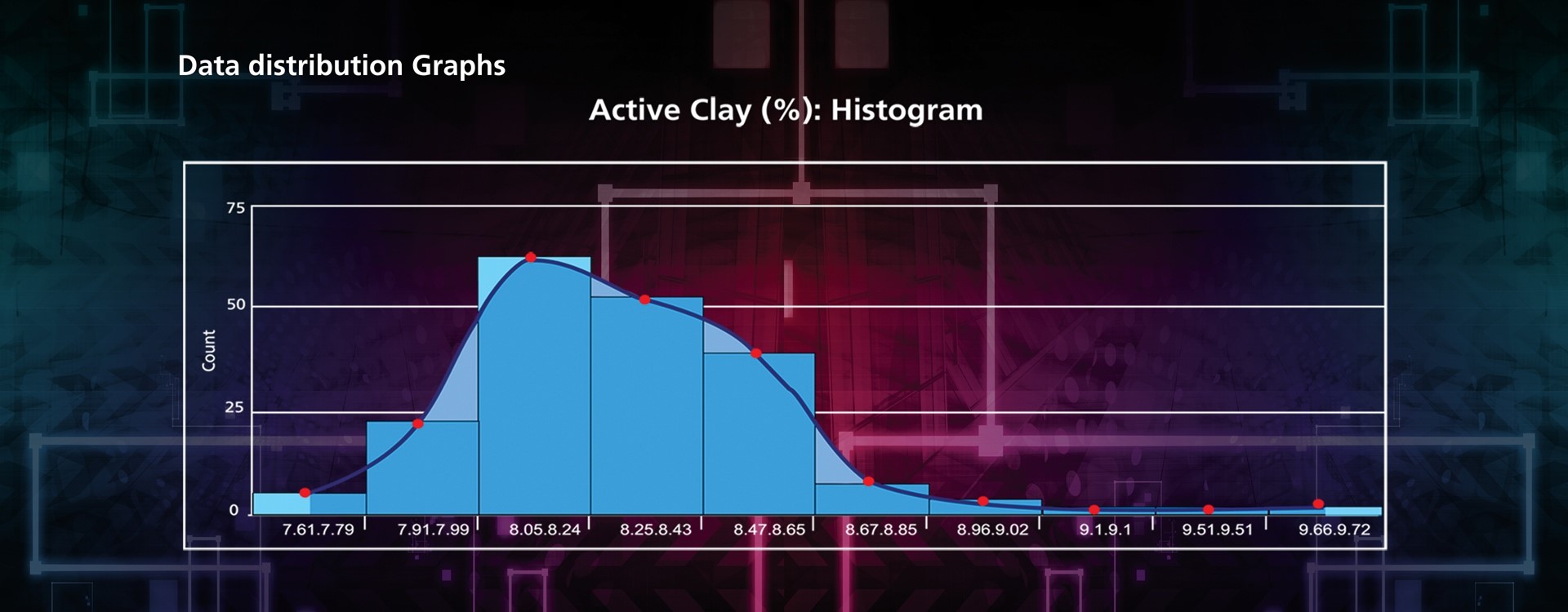

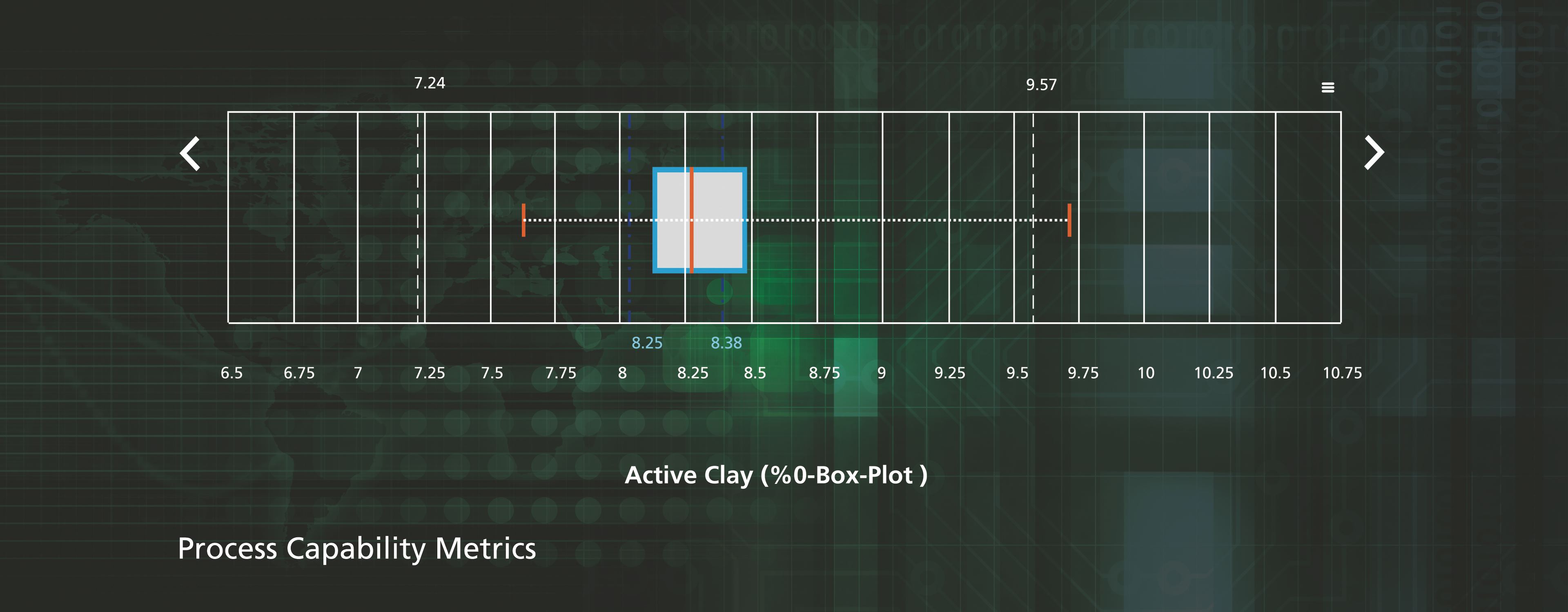

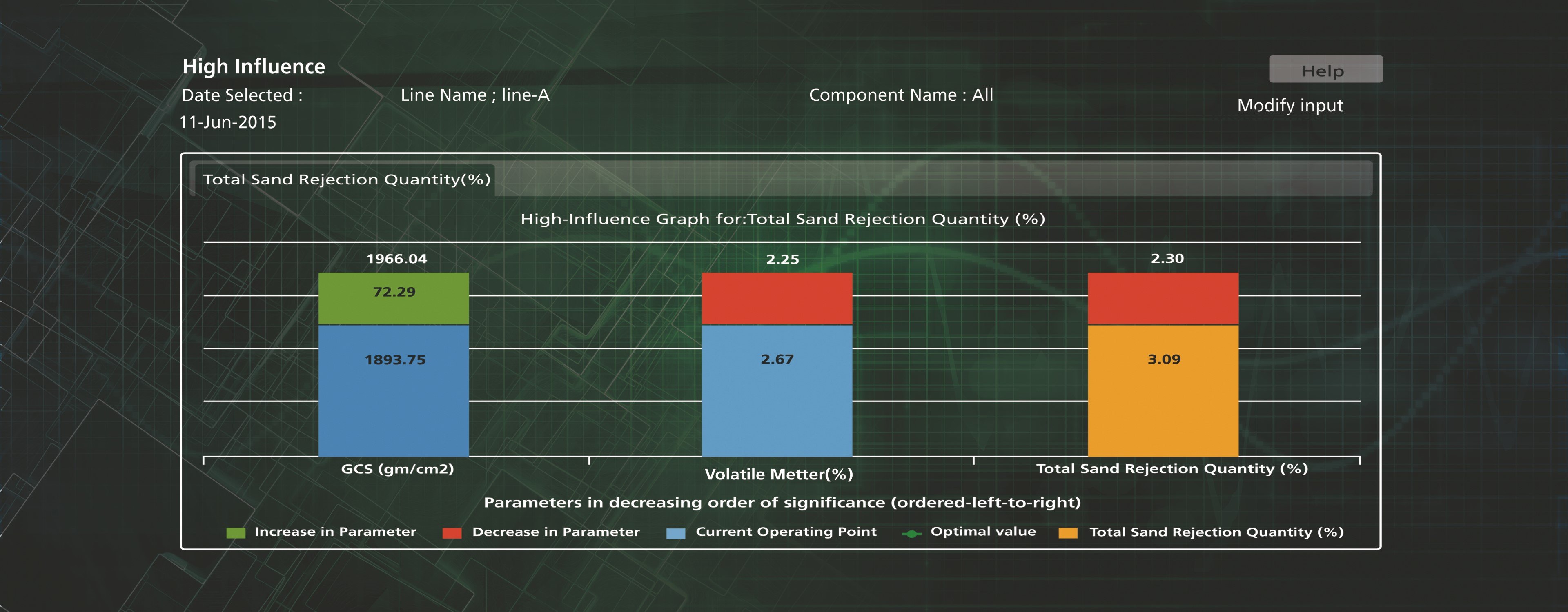

"SANDMAN" uses data analytics to help you face these challenges. It is the world's first specialized computer software for foundries. It's powerful mathematical modelling and algorithm will enable optimizing molding sand control, dose-by-need additive consumption, and reduce toxic waste. It will minimise the stress of critical decision making. And give you an edge over the competition.

Deploy SANDMAN and take your business to the next level.

Call or email us to know more. Do it now to boost your metal casting quality and business outcomes.

044 4959 7202

044 4959 7202

About Sandman

The genesis of SANDMAN lay in the providing of solutions in green sand, which Mr. Deepak Chowdhary introduced in the early 1990's. Inviting foundries to send their laboratory samples of green sand and additives, he was able to predict the possible casting defects, causes and their possible solutions based on some fundamental parameters of the sand sample. The predictions , based on his growing experience dealing with several hundred foundries that his company supplied additives to, proved to be quite accurate and thus commanded consistent interest and demand from customers and became a significant value proposition.

INTRODUCTION TO SANDMAN

Did you know?

FROM THE CEO'S DESK